X2JET Plus Touch

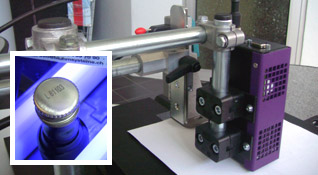

Sophisticated controller with a color touch-screen and a very intuitive user interface with icons. Up to two printheads can be connected. This controller is the evolution of the popular Compactline 2.5 system.

Universal Controller

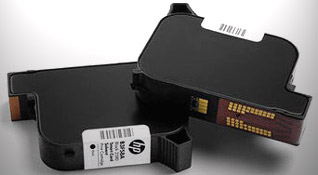

Connect any type of printhead from Mark-o-Print to your controller. TIJ (Thermal Inkjet) technologies from HP® or Funai®, or Piezoelectric technologies from Trident® or Xaar®, it is your choice and you can benefit from a wider range of ink types available, in many colors and for any surface.

Bundled Software

The system includes the software to create texts and start print jobs, manage configurations and monitor all the controllers in your factory. With no extra cost at all! Know more at iDesign.

Double the Potential

You can connect one or two printheads to the controller. Increase the print height, print in both sides of the same product or you can even print on two production lines.

Control 2 Conveyors at the Same Time

With two printheads you can control two production lines. Each printhead can print on products that travel on different conveyor belts. The printheads can be printing distinct texts and use completely different print parameters, such as the print speed or the print delay (distance of the printed text to the edge of the product). You can connect two product sensors and two encoders using a splitter cable.

High-Quality Prints at Incredible High-Speeds

Print in high resolutions to obtain impressive and sharp texts with smooth outlines without aliasing effects whatsoever. And you certainly will not need to slow down the velocity of your production line conveyor, because the system can reach unbelievable print speeds.

No Need for PC

Work comfortably with the controller thanks to its large 5.7 inches screen and QWERTY keyboard. You can do everything directly on the controller, including the change of the configurations, the text creation and edition and start printing after filling in all the variable fields.

Design the Texts at the PC or Directly on the Controller

Design the print texts comfortably on the PC using the iDesign software or do it directly on the controller. The controller allows you to create new texts from scratch without needing a computer and you can make changes to already existing layouts.

Make Simple or Complex Print Texts

The controller has an internal clock so that you can print dates and expiration dates automatically. Besides that, you can put text with any font and style, barcodes, images and many more things. Learn about everything you can do by visiting the iDesign software page.

Barcodes that are Always Readable

Use a shaft encoder to always keep the system synchronized with the effective conveyor speed and print 1D and 2D barcodes on any surface. It is possible to enable and configure a barcode correction algorithm that predicts the ink overflowing outside the intended boundaries on materials where the ink smudges, and shaves off certain pixels. The results are incredible and it really works!

Send and Receive

Transfer print texts and files such as fonts and images, from the PC to the controller or import them from the controller to the PC. You can do the communication using any connection type: USB (using a cable or stick), Ethernet or RS232 (requires adaptor cable).

Maintenance Free

With IP40 protection, these controllers are very sturdy and reliable, with lifespans that go over 15 years. And if you pick a TIJ (Thermal Inkjet) printhead with technology from HP® or Funai®, you can say goodbye to clogs, cleaning and maintenance tasks. When you change the cartridge, you get brand new nozzles again.

Where You Think It's Best

You can mount the controller using the universal bracket to fix it on the production line or on a wall. Or you can simply place the controller on top of a table.

Cost per Print is Almost Zero and Without Interruptions

A single cartridge can easily last for tenths or even hundreds of thousands of prints and a bottle lasts for much longer. Surely, it all depends on the kind of text that you want to print, the configurations and ink type, but normally the costs per prints are a tiny fraction of a cent. Few cartridge changes are needed and, if you use a printhead with redundant Non-Stop Printing technology, it is possible to change the cartridge without having to stop the production line and no product passes without being marked. There are also ink supplying tanks available for cartridges, which are connected with a tube to keep the cartridge always at full capacity.

Smart Cartridges

Know the exact ink level in the cartridges at any time. Besides informing the controller about the ink level, the printhead also sends cartridge data to the controller, to configure the print parameters automatically depending on the ink type that is being used.

Have Full Print Control

You can print on products that travel from the left to the right or from the right to the left, by changing a simple configuration. Choose the resolution, the speed, the zoom and the orientation (normal, upside down or mirrored). The printheads have two nozzle rows (A and B) and you can control how to use them. In the normal mode, the controller alternates between the two rows (A~B). If a row has defective nozzles, you can choose to exclusively use the other row. When using a shaft encoder to have a precise control of the print speed, you can opt to use both rows at the same time (A+B) to obtain even darker print results.

Receive Warnings

The controller includes 3-color warning LEDs and shows status messages on the screen. You can also connect an optional alarm lamp (with or without buzzer) to the controller.

Quiet and Energy Efficient

This system consumes less energy than a computer and does not have any fans, which makes it completely quiet, not to mention that the internal components are protected from dust accumulation.

The Integrator's Paradise

The controller allows several input and output signals, so that you can synchronize the system with your production line. The input signals are configurable to work in PNP or NPN using the iDesign software. As inputs, you can send signals to: invert the print direction, rotate the print 180 degrees, stop the print (does not print while the signal is active), pre-warm the cartridge, change the text being printed (switch between 4 texts), among others. As for the outputs, you can know if the tank has low ink, if the tank is empty, if the system is green (ok), if the system has warnings, if the system is in error and if the system is ready to print or a print was triggered.

Approved by Programmers

The communication with the controllers is completely clear. The saved texts (the "labels" that are printed directly on the products) are pure text files that can be read and modified in any programming language. The format of the commands for communication and for text creation ("labels") are all well-documented and we can provide such documentation. Dedicated software can be developed to send or receive texts and configurations and to start print jobs using a network connection or USB/RS232 communication.

Approved by System Integrators

With the Weber® policy for Global Export, the system integrator companies can export our inkjet systems as part of a bigger system and the final user gets all the technical support in the destination country, performed by the local distributor of that said country, all completely transparent and without additional costs. All that a system integrator must do is mention that the system is for resale and when the destination country is known, inform us about it so that we can proceed with the transfer of responsibility of the system to the local distributor.

Pick Your Version

If you do not need every single feature, you can obtain a better price by choosing a more basic version. And the best is that you can, at any moment, do an upgrade to a higher version. You only need to tell us the serial number or MAC address of the system and we will send you an activation code to unlock your controller. The differences of each version are shown on the table below:

| Function | Advanced | Pro |

|---|---|---|

| Max. Number of Printheads | 2 | 2 |

| Horizontal Resolution [dpi] | 900 | 900 |

| Vertical Resolution [dpi] | 600 | 600 |

| Print Speed (at 300 dpi) [m/min] | 90 | 240 |

| Print Length (at 300 dpi) [m] | 1 | 3 |

| Includes iDesign Software | ✔︎ | ✔︎ |

| Color Touch-Screen | ✔︎ | ✔︎ |

| QWERTY Keyboard | ✔︎ | ✔︎ |

| Max. Number of Texts | Unlimited | Unlimited |

| Text Creation and Edition at the Controller | ✔︎ | ✔︎ |

| Text Fields | ✔︎ | ✔︎ |

| Logos | ✔︎ | ✔︎ |

| Date and Time | ✔︎ | ✔︎ |

| Date Offsets (expirations) | ✔︎ | ✔︎ |

| Counters | ✔︎ | ✔︎ |

| Variables | ✔︎ | ✔︎ |

| Variable Entry at the Controller | ✔︎ | ✔︎ |

| Shift Codes | ✔︎ | ✔︎ |

| Action Fields (references) | ✔︎ | ✔︎ |

| Barcodes | ✔︎ | ✔︎ |

| 2D Barcodes | ✔︎ | ✔︎ |

| Password Protected Menus | 🛇︎ | ✔︎ |

| Database Printing | 🛇︎ | ✔︎ |

| Configurable I/Os | ✔︎ | ✔︎ |

| Copy with USB-Pen (USB-A) | ✔︎ | ✔︎ |

| USB Connection to the PC (USB-B) | ✔︎ | ✔︎ |

| Ethernet | ✔︎ | ✔︎ |

| RS232 | ✔︎ | ✔︎ |

| RS422 | ✗︎ | ✗︎ |

| Wireless LAN | ✗︎ | ✗︎ |

| Bluetooth | ✗︎ | ✗︎ |

Specifications

-

Type

Inkjet Controller

-

Brand

Mark-o-Print

-

Model

X2JET Plus Touch

-

Max. Number of Printheads

2

-

Max. Number of Controllable Production Lines

2

-

Supported TIJ Technologies

HP and Funai (compatible only with our Mark-o-Print printheads)

-

Supported Piezo Technologies

Trident and Xaar (compatible only with our Mark-o-Print printheads)

-

Print Height

Depends on the connected printheads

-

Print Length

3m (at 300dpi with Pro version)

-

Maximum Resolution

900x600dpi (depends on the chosen printhead, requires low speed)

-

Top Print Speed

720m/min (with Pro version, depends on the chosen printhead, requires low resolution)

-

PC Software

iDesign (included)

-

User Interface

TFT 5.7" Color Touch-Screen

QWERTY Keyboard plus shortcut buttons

3-color LEDs (green, yellow, red) -

Memory for Storing Texts, Logos and Fonts

1GB (expandable to 32GB)

-

Protection

IP40

-

System Languages

English

German

French

Spanish -

Ports

2x Head

1x USB-A

1x USB-B

1x Ethernet

1x Sensor

1x Encoder

1x Alarm

1x I/O

1x Power Connection -

Additional ports with cable at the I/O port

(cable not included)

1x Sensor

1x Encoder

1x Alarm

1x RS232 -

Electrical

90 ~ 240V AC, 50/60Hz / max. 60W

-

Weight

2,85kg

-

Dimensions (Width x Depth x Height)

231mm x 219mm x 108mm

-

Typical Accessories

Printheads

Controller Bracket

Encoder (recommended when printing barcodes)

Product Sensor

Splitter Cable

Alarm Lamp

UV Lamp

more accessories

Alternative Products

-

X4JET Plus Touch ▶︎

Universal ControllerUp to 4 Printheads

HP, Funai, Trident, Xaar -

integra Quadro² ▶︎

Universal ControllerUp to 8 Printheads

HP, Funai, Trident, Xaar -

integra One ▶︎

All-in-One Printhead1 Printhead of 12,5mm

HP Technology -

X1JET HP ▶︎

All-in-One Printhead1 Printhead of 12,5mm

HP Technology

Check Also:

Disclaimer

The final version of the delivered system may not

match entirely with the presented images and specifications.