X1JET XR

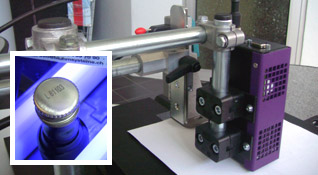

All-in-one printhead with a built-in controller. It is very compact and has a basic user interface. It was thought for integration and to be controlled remotely via PC or an automatism.

No More Cables Between Printhead and Controller

This printhead is completely independent. With its focus on integration, the interaction with the operator is minimal: only the ink tank needs to be refilled from time to time. The text selection and configuration changes are done remotely via PC with the iDesign software or automatisms. Even so, it still has three buttons that allow the execution of the most frequent tasks.

Xaar® Technology

With Piezoelectric technology from Xaar, these printheads can control 500 individual nozzles and are recommended to those who print a lot, given that the price per liter of ink is very low.

Bundled Software

The system includes the software to create texts and start print jobs, manage configurations and monitor all the controllers in your factory. With no extra cost at all! Know more at iDesign.

Print Bigger

Print texts with heights up to 71mm with a single printhead, which makes everything easier and avoids joining problems when the alignments are not perfect.

Directly Change Settings and Start Prints

Even though it was designed to be managed remotely, the X1JET XR still has 3 buttons that make possible, among other tasks, the selection of one of nine available texts, the start or stop of the print job and the change of the delay (to move the text closer or farther away from the edge of the product).

Local Control with optional HMI

By connecting an optional HMI, you open up new possibilities. You can perform tasks such as changing configurations, select the text and start the print job after typing in the variables directly on the controller. The high-resolution OLED screen shows animated icons and it is very easy to navigate through the menus with the iLogik button. A short click to enter and confirm changes and holding the button a little longer cancels and goes back to the menu above. Turning the button, you can change the values very quickly and intuitively, even when you need to input text. You will only believe how easy it is when you try it.

Design Texts at Your PC

Create print texts comfortably at the PC using the iDesign software and transmit them easily to the controller.

Make Simple or Complex Print Texts

The controller has an internal clock so that you can print dates and expiration dates automatically. Besides that, you can put text with any font and style, barcodes, images and many more things. Learn about everything you can do by visiting the iDesign software page.

Barcodes that are Always Readable

Use a shaft encoder to always keep the system synchronized with the effective conveyor speed and print 1D and 2D barcodes on any surface. It is possible to enable and configure a barcode correction algorithm that predicts the ink overflowing outside the intended boundaries on materials where the ink smudges, and shaves off certain pixels. The results are incredible and it really works!

Send and Receive

Transfer print texts and files such as fonts and images, from the PC to the controller or import them from the controller to the PC. You can do it using an USB stick, an Ethernet connection or via RS232 (requires adaptor cable).

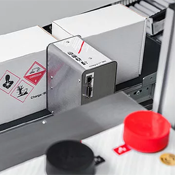

Side or Top Printing

You can fixate the printhead using the Top version available with several hose lengths and a special bracket for printing on top of products, or using the Compact or Vario versions for side printing, without the hose. The Vario version has an articulation that allows a slight turning of the printhead for small adjustments of its alignment to the product.

Cost per Print is Almost Zero and Without Interruptions

A single bottle can easily last for hundreds of thousands of prints and contains around ten times more ink than a cartridge at a much more affordable price. Surely, it all depends on the kind of text that you want to print, the configurations and ink type, but normally the costs per prints are a tiny fraction of a cent.

Have Full Print Control

You can print on products that travel from the left to the right or from the right to the left, by changing a simple configuration. Choose the resolution, the speed, the zoom and the orientation (normal, upside down or mirrored). The printheads have two nozzle rows (A and B) and you can control how to use them. In the normal mode, the controller alternates between the two rows (A~B). If a row has defective nozzles, you can choose to exclusively use the other row. When using a shaft encoder to have a precise control of the print speed, you can opt to use both rows at the same time (A+B) to obtain even darker print results.

Receive Warnings

The controller includes 3-color warning LEDs. You can also connect an optional alarm lamp (with or without buzzer) to the controller.

The Integrator's Paradise

The controller allows several input and output signals, so that you can synchronize the system with your production line. The input signals are configurable to work in PNP or NPN using the iDesign software. As inputs, you can send signals to: invert the print direction, rotate the print 180 degrees, stop the print (does not print while the signal is active), pre-warm the printhead, change the text being printed (switch between 4 texts), among others. As for the outputs, you can know if the tank has low ink, if the tank is empty, if the system is green (ok), if the system has warnings, if the system is in error and if the system is ready to print or a print was triggered.

Approved by Programmers

The communication with the controllers is completely clear. The saved texts (the "labels" that are printed directly on the products) are pure text files that can be read and modified in any programming language. The format of the commands for communication and for text creation ("labels") are all well-documented and we can provide such documentation. Dedicated software can be developed to send or receive texts and configurations and to start print jobs using a network connection or USB/RS232 communication.

Approved by System Integrators

With the Weber® policy for Global Export, the system integrator companies can export our inkjet systems as part of a bigger system and the final user gets all the technical support in the destination country, performed by the local distributor of that said country, all completely transparent and without additional costs. All that a system integrator must do is mention that the system is for resale and when the destination country is known, inform us about it so that we can proceed with the transfer of responsibility of the system to the local distributor.

Pick Your Version

If you do not need every single feature, you can obtain a better price by choosing a more basic version. And the best is that you can, at any moment, do an upgrade to a higher version. You only need to tell us the serial number or MAC address of the system and we will send you an activation code to unlock your controller. The differences of each version are shown on the table below:

| Function | Basic | Advanced | Pro | |

|---|---|---|---|---|

| Max. Number of Printheads | 1 | 1 | 1 | 1 |

| Print Height [mm] | 71 | 71 | 71 | 71 |

| Horizontal Resolution [dpi] | 600 | 600 | 600 | 600 |

| Vertical Resolution [dpi] | 180 | 180 | 180 | 180 |

| Print Speed at 300dpi [m/min] | 30 | 30 | 60 | 67 |

| Print Length (at 300 dpi) [m] | 1 | 1 | 1 | 2 |

| Includes iDesign Software | ✔︎ | ✔︎ | ✔︎ | ✔︎ |

| OLED Display | ✗︎ | ✗︎ | w/ HMI | w/ HMI |

| Max. Number of Texts | 9 | 9 | 9 | 9 |

| Text Creation and Edition at the Controller | ✗︎ | ✗︎ | ✗︎ | ✗︎ |

| Text Fields | ✔︎ | ✔︎ | ✔︎ | ✔︎ |

| Logos | ✔︎ | ✔︎ | ✔︎ | ✔︎ |

| Date and Time | 🛇︎ | ✔︎ | ✔︎ | ✔︎ |

| Date Offsets (expirations) | 🛇︎ | 🛇︎ | ✔︎ | ✔︎ |

| Counters | 🛇︎ | 🛇︎ | ✔︎ | ✔︎ |

| Variables | 🛇︎ | 🛇︎ | ✔︎ | ✔︎ |

| Variable Entry at the Controller | 🛇︎ | 🛇︎ | w/ HMI | w/ HMI |

| Shift Codes | 🛇︎ | 🛇︎ | ✔︎ | ✔︎ |

| Action Fields (references) | 🛇︎ | 🛇︎ | ✔︎ | ✔︎ |

| Barcodes | 🛇︎ | 🛇︎ | ✔︎ | ✔︎ |

| 2D Barcodes | 🛇︎ | 🛇︎ | 🛇︎ | ✔︎ |

| Password Protected Menus | ✗︎ | ✗︎ | ✗︎ | ✗︎ |

| Database Printing | 🛇︎ | 🛇︎ | 🛇︎ | ✔︎ |

| Configurable I/Os | ✔︎ | ✔︎ | ✔︎ | ✔︎ |

| Copy with USB-Pen (USB-A) | ✔︎ | ✔︎ | ✔︎ | ✔︎ |

| USB Connection to the PC | ✗︎ | ✗︎ | ✗︎ | ✗︎ |

| Ethernet | ✔︎ | ✔︎ | ✔︎ | ✔︎ |

| RS232 | ✔︎ | ✔︎ | ✔︎ | ✔︎ |

| RS422 | ✗︎ | ✗︎ | ✗︎ | ✗︎ |

| Wireless LAN | ✗︎ | ✗︎ | ✗︎ | ✗︎ |

| Bluetooth | ✗︎ | ✗︎ | ✗︎ | ✗︎ |

Specifications

-

Type

Inkjet Printhead with Built-In Controller

-

Brand

Mark-o-Print

-

Model

X1JET XR Compact

X1JET XR Vario

X1JET XR Top -

Max. Number of Printheads

1

-

Max. Number of Controllable Production Lines

1

-

Technology

Piezoelectric from Xaar®

-

Print Height

71mm

-

Print Length

2m

-

Maximum Resolution

600x180dpi

-

Top Print Speed

200m/min (with Pro version, requires low resolution)

-

PC Software

iDesign (included)

-

User Interface

3 Buttons

3-color LEDs (green, yellow, red)

HMI with 128x68px OLED Display (optional with Advanced version or higher) -

Memory for Storing Texts, Logos and Fonts

32MB (optionally extendable a 1GB)

-

Protection

IP40

-

Ports

1x USB-A

1x Ethernet

1x I/O

1x Power Connection -

Additional ports with cable at the I/O port

(cable not included)

1x Sensor

1x Encoder

1x Alarm

1x RS232 -

Ink Tank Capacity

500ml Bottles

-

Electrical

90 ~ 240V AC, 50/60Hz / max. 50W

-

Weight

5kg (with empty tank)

-

Dimensions (Width x Depth x Height)

187mm x 316mm x 306mm (with ink bottle)

-

Typical Accessories

Tank Bracket

Printhead Bracket (for side printing)

Printhead Bracket (for top printing)

External Product Sensor

Encoder (recommended when printing barcodes)

HMI

Splitter Cable

Alarm Lamp

more accessories

Alternative Products

-

integra PP 108 ▶︎

All-in-One Printhead1 Printhead of 108mm

Seiko Technology -

integra PP 108 Bicolor ▶︎

All-in-One Printhead1 Printhead of 108mm (2-color)

Seiko Technology -

X1JET MX 100 Vario ▶︎

All-in-One Printhead1 Printhead of 100mm

Trident Technology -

X2JET Plus Touch ▶︎

Universal ControllerUp to 2 Printheads

HP, Funai, Trident, Xaar

Check Also:

Disclaimer

The final version of the delivered system may not

match entirely with the presented images and specifications.