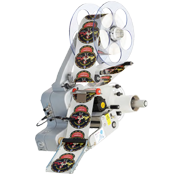

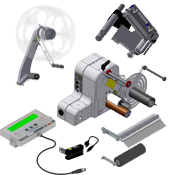

Alpha Compact 120/150 TB

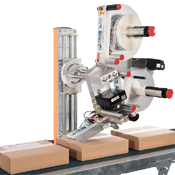

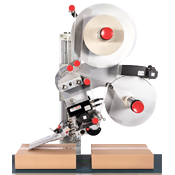

A very compact and light labeling system, but at the same time, very robust and reliable. The TB models are a version of the popular Alpha Compact that use the Tamp-Blow application method.

Apply Labels at High Speeds

Do not limit your productivity! With the Alpha Compact 120 TB, apply labels with widths up to 120mm onto products that travel at speeds up to 50m/min without requiring stops. On the other hand, the wider model, the Alpha Compact 150 TB, allows widths up to 150mm at speeds of 40m/min.

Different Applications

Apply labels on the lids and the top of the products or on the side of boxes or flat-sided bottles. With a single stand, you can adjust the system to apply on any position and the labeler is available in left- or right-hand versions (LH/RH).

Excellent Precision

Apply your labels in the right spot with millimeter precision. No more misplaced, crooked or wrinkled labels.

Easy to Use

This system is very easy to set-up. You just need to calibrate the labeler once to the label size being used. After tuning the positioning, just let it do the job. The system detects missing labels on the roll and advances automatically to the next one, so no product will pass unlabeled. The digital HMI is included and the display allows you to easily change configurations and read status messages.

Few Stops

With an unwinder that allows big label rolls and a rewinder for the label liner that works in 1:1, that is, with capacity to rewind the complete roll, you will have to make few stops to do label roll replacements.

Industrial Motor

The labeler is moved by a powerful stepper motor that allows precise and fast feeding of the labels to the tamp pad.

Label Counter

The digital HMI display shows a label counter so that you know how many application cycles were performed. The counter has a capacity for 10 000 applications and then starts over automatically. You can reset the counter at any moment or you can use a countdown feature by setting the counter to a value greater than zero. In that case, the labeler will automatically stop the labeling process when the counter reaches zero.

With Standard Tamp Applicator

The label applicator uses the popular Tamp-Blow method that makes it possible to apply labels, on the top or on the side of moving products, without contacting with them or requiring stops. The application arm has an adjustable stroke up to 250mm and, with an optional proximity sensor installed on the tamp, it will be able apply on products that have different heights.

High Quality Sturdy System

These labelers are very robust and reliable, with a lifespan that goes over 15 years. Built exclusively with quality materials, you will not find a single speck of rust and, besides the occasional cleaning of possible label adhesive build-up, they do not require neither lubrication or maintenance.

Operational Redundancy

For the most demanding applications, we have an optional controller for Zero Down Time into which you can connect two Alpha Compact systems. Only one system is labeling, but if the labels run out or an error occurs, the controller automatically switches the labeling operation to the other system. Thus, you can replace the label rolls without needing to stop the production line and no product passes through unlabeled.

Safe and Certified Systems

These systems have CE certification and follow all European safety norms. Most of the standard system are complete complying systems (CC) with the safety norms and do not require additional protections or safeguards, given the fact that they do not exert forces over 50N. When the application rate is critical, there are faster versions in which the system is unlocked to go beyond the 50N of force threshold, being these versions identified as NC (not completed), since they require additional safeguards. If you choose a NC version, the system will include door-open sensors that will immediately halt the labeling operation when the safeguards are opened, so that the system cannot cause injuries. Furthermore, they also bring emergency kill switches to immediately stop the system manually.

Quiet and Energy Efficient

A system that applies labels like a machine-gun must consume a lot of power and be very loud... Or not! This system consumes as much power as a computer and without fans it is relatively quiet, keeping the noise emission below 80dB(A).

Easy Integration

The system can receive remote signals to trigger the application. The input signals work in active and passive modes, that is, the 24V can be sent by the PLC or supplied by the labeler itself. Like this, only a contact needs to be switched. As for the output signals, the labeler informs if it is in normal or in error conditions, if the label roll is near the end and can also send a synchronization signal that can be configured to be active during or after the application cycle, in the last scenario, allowing a definition of a delay and duration in which the signal will be active.

Approved by System Integrators

With the Weber® policy for Global Export, the system integrator companies can export our labeling systems as part of a bigger system and the final user gets all the technical support in the destination country, performed by the local distributor of that said country, all completely transparent and without additional costs. All that a system integrator must do is mention that the system is for resale and when the destination country is known, inform us about it so that we can proceed with the transfer of responsibility of the system to the local distributor.

Specifications

-

Type

Label Applicator

-

Brand

Weber

-

Models

Alpha Compact 120 TB LH (Left-Hand Version)

Alpha Compact 120 TB RH (Right-Hand Version)

Alpha Compact 150 TB LH (Left-Hand Version)

Alpha Compact 150 TB RH (Right-Hand Version) -

Maximum Label Feed Speed

50m/min (Alpha Compact 120 TB)

40m/min (Alpha Compact 150 TB) -

Application Rate

Depends on the application

-

Minimum Label Width

50mm

-

Maximum Label Width

120mm (Alpha Compact 120)

150mm (Alpha Compact 150) -

Minimum Label Length

40mm

-

Maximum Label Length

160mm

- Application Methods

-

Application Stroke

Adjustable up to 226mm

-

Tamp-Pad Sizes

120x45mm

120x90mm

120x160mm

160x120mm

(drilled for 1 label size) -

Label Placement

-

Side

Side

-

Top

Top

-

Side (Flat Bottles)

Side (Flat Bottles)

-

Top (Lids)

Top (Lids)

-

Among others...

Among others...

-

-

Application Accuracy

±1,5mm

-

Motor Type

Stepper

-

Core Diameter

76mm (optionally 40mm)

-

Unwinder Capacity

300mm External Diameter (approx. 450m)

-

Rewinder Capacity

1:1

-

PC Software

None (not needed)

-

User Interface

Digital HMI with a 2-line Display

-

Languages (Digital HMI, Pack 2)

English

Portuguese

Spanish

Polish

Czech

Latvian

Russian -

Protection

IP40

-

Ports

1x Product Sensor

1x Label Sensor (to calibrate positioning)

1x Low Label Sensor (to light yellow alarm)

1x Alarm Lamp

1x Encoder (optional)

1x HMI

1x I/O

1x Applicator

1x USB-B

1x Power Connection -

Electrical

115 a 230V AC, 50/60Hz / max. 300W

-

Compressed Air

6bar

-

Weight

Approx. 22kg (Alpha Compact 120)

-

Dimensions (Width x Depth x Height)

175mm x 310mm x 590mm (Alpha Compact 120)

-

Noise Emission

< 80dB(A)

-

Typical Accessories

Stand

Product Sensor

Low Label Sensor

Proximity Sensor on Tamp-Pad (variable stroke)

Alarm Lamp

Zero Down Time Controller

more accessories

Alternative Products

-

Alpha Compact 150 ▶︎

Labeler150mm, 40m/min, Wipe-On

RH or LH Versions -

Alpha Modular ▶︎

LabelerCustomized

RH or LH Versions -

Alpha HSM 135 ▶︎

Labeler135mm, 100m/min, Wipe-On

RH or LH Versions -

Alpha HSM 200 ▶︎

Labeler200mm, 80m/min, Wipe-On

RH or LH Versions

Check Also:

Disclaimer

The final version of the delivered system may not

match entirely with the presented images and specifications.