Labeling Systems

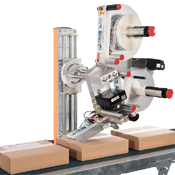

To precisely apply labels automatically at high speeds makes all the difference, reducing costs and increasing your productivity. The labeling systems from Weber® are very reliable, robust and compact. It is possible to apply pre-printed labels in all kinds of products and packages, like boxes, bottles or cans. Labels can be applied at any position in the final product (front, rear, side, top or bottom), in the corners, or even in two sides at the same time. The applicator can work with or without contact with the products.

- Extremely precise placement of the labels with error margins inferior to 1mm

- Very high speeds and application rates

- Reduces labor costs and assures a fast, efficient and productive labeling

- Different application methods so that the system can perfectly adapt to your products

- Adjustable stands to fit the system in your production line

- Print batch numbers and dates by coupling a X1JET coding system

- Easy integration

- And much more...

-

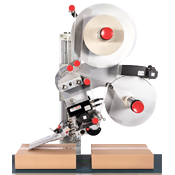

Alpha Entry ▶︎

Labeler120mm, 30m/min, Wipe-On

RH or LH Versions -

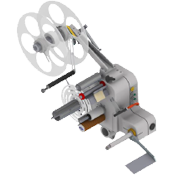

Alpha Compact 120 ▶︎

Labeler120mm, 50m/min, Wipe-On

RH or LH Versions -

Alpha Compact 150 ▶︎

Labeler150mm, 40m/min, Wipe-On

RH or LH Versions -

Alpha Compact 120 TB ▶︎

Labeler120mm, 50m/min, Tamp-Blow

RH or LH Versions -

Alpha Compact 150 TB ▶︎

Labeler150mm, 40m/min, Tamp-Blow

RH or LH Versions -

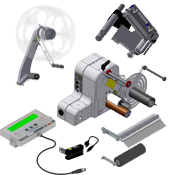

Alpha Modular ▶︎

LabelerCustomized

RH or LH Versions -

Alpha HSM 135 ▶︎

Labeler135mm, 100m/min, Wipe-On

RH or LH Versions -

Alpha HSM 200 ▶︎

Labeler200mm, 80m/min, Wipe-On

RH or LH Versions -

Alpha HSM 260 ▶︎

Labeler260mm, Wipe-On

RH or LH Versions -

Alpha HSM 320 ▶︎

Labeler320mm, 60m/min, Wipe-On

RH or LH Versions -

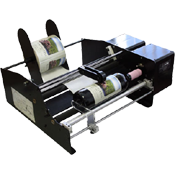

Bottle-Matic ▶︎

Semi-Automatic Labeler406mm, 115mm/s, Wrap-Around

For Bottles and Cylinders -

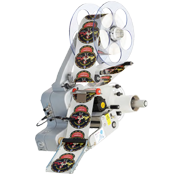

Geset Lines ▶︎

Labeling LinesDifferent Application Methods

Multiple Systems

Notes about the Models:

-

Alpha Entry

Basic entry model, with a minimum of 3 systems per order for an incredibly and unbeatable low cost per unit. -

Alpha Compact 120/150

Applicator powered by a stepper motor that applies labels up to widths of 120 or 150mm respectively, using the Wipe-On application method. -

Alpha Compact TB

Version with a tamp applicator that uses the Tamp-Blow application method. -

Alpha Modular

Build it yourself: you can choose the various components that makes your labeling systems, such as the kind of motor, rewinder, unwinder, applicator, among other details. The applicator is assembled as per your requested configuration and fully tested before being delivered. -

Alpha HSM

Enhanced and reinforced system when compared to the Alpha Compact, equipped with a servo motor to apply labels with widths up to 320mm at very high speeds using the Wipe-On method. -

Bottle-Matic

Apply labels onto bottles, cans, tins and other cylindric products using the Wrap-Around method. With manual product feeding, this semi-automatic labeler is available in 4 versions to apply a single label or two labels at a time (front and back label), for label widths of 250 or 406mm. -

Geset Lines

Multiple systems with a small conveyor belt and one or more labeling systems. Each model is designed to apply labels in a very specific type of product.