Geset Lines

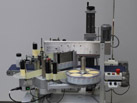

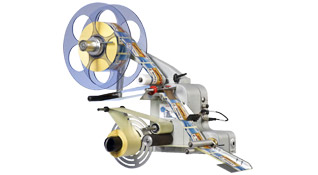

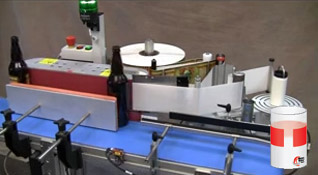

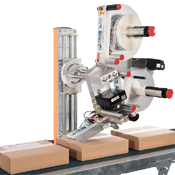

These systems integrate one or more label applicators mounted on conveyor belts with special product alignment guides and pressure rolls, so that you can apply labels onto products with more complicated shapes than the normal card boxes, such as flask and bottles. There are several models for different product shapes and application types (two-sided applications, wrap-around, bottom labeling, among other applications). The labelers used are generally the Alpha Compact or the Alpha HSM.

The Perfect System for Each Application

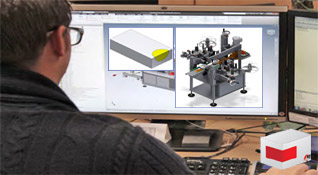

The Geset Lines are systems that besides the label applicators also include a special-tailored conveyor for the type of application and product that is going to be labeled. There are more than 50 distinct modules, and so, creating a line for your specific product will not be a problem.

Apply Labels in Any Product Shape

No matter your product shape, we can adapt the systems to practically any kind of form and product, be it a very light one or a heavy one. The systems are design in a way that you can apply the label and, in many cases, also the back-label in your specific products.

Excellent Precision

Apply your labels in the right spot with millimeter precision. No more misplaced, crooked or wrinkled labels.

Apply Labels at High Speeds

Do not limit your productivity! These lines can reach speeds of about 50m/min, with application rates around 500 products per minute, which means 30 000 or so applications per hour.

Blends with Your Production Line

The height of the base can be arranged according to your needs and the system can still be adjusted thanks to its adjustable feet, in order to fit the conveyor of the Geset Line perfectly in between your already existing production line conveyors on your factory.

Fully Adjustable System

The systems allow small variations in product sizes, having movable alignment guides and cranks for vertical and horizontal adjustments of the applicator systems, so that the label is applied exactly where you want it.

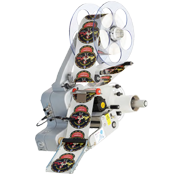

Includes the Labelers

Besides the conveyor, the lines already include one or, if you also want to apply a back-label, two high quality label applicators. The preferred labeling system is usually the Alpha Compact but, for the more demanding ones, the Alpha HSM can be used.

Easy to Use

It is very easy to reload and calibrate the labelers and once the movable guides and the horizontal and vertical positions of the applicators are aligned, all you have to do is feed the conveyor with the products. You can move the sensors or configure the application delay to place the labels more to the front or to the rear of the products. With two persons, the system can be used with manual product feeding, with one person placing the products on the conveyor and another person to remove the already labeled products at the end.

High Quality Sturdy System

These systems are very robust and reliable, with a long lifespan. Built exclusively with quality materials, you will not find a single speck of rust and, besides the occasional cleaning of possible label adhesive build-up, they do not require neither lubrication or maintenance.

Safe and Certified Systems

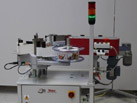

These systems have CE certification and follow all European safety norms. They also bring emergency kill switches to immediately stop the system.

Say Goodbye to Compressed Air

Most of the models do not even require compressed-air. The labelers usually use the Wipe-On method that besides allowing the application of labels in many positions and without stopping the production line, it also does all that without needing compressed-air. This means greater cost reductions and less maintenance.

Quiet and Energy Efficient

The conveyor and the labelers are considerably quiet and, taking in account that we are talking about a very fast industrial system, the energetic consumptions are quite low.

Approved by System Integrators

With the Weber® policy for Global Export, the system integrator companies can export our labeling systems as part of a bigger system and the final user gets all the technical support in the destination country, performed by the local distributor of that said country, all completely transparent and without additional costs. All that a system integrator must do is mention that the system is for resale and when the destination country is known, inform us about it so that we can proceed with the transfer of responsibility of the system to the local distributor.

Geset Lines Models

Geset 112

System with two separate conveyors. An Alpha labeler is placed upside-down in the small gap between the two conveyors, so that you can place labels in the bottom of your products. The system can reach application rates of about 100 products per minute. The Wipe-On method is used, and as a result, compressed-air is not needed. For double application on both the bottom and on top, check also the Geset 117 model.

Geset 114

A very popular system given its simplicity and application precision. The system uses two Alpha labelers, one at each opposing sides of the conveyor, to label on both sides simultaneous. The products can be boxes or flat-sided bottles. The line is ready for light products, so, to get additional stability and traction, a second conveyor is used above the products (see video). The labels and back-labels can be applied up to 20m/min at rates of 80 products per minute. The Wipe-On method is used, and as a result, compressed-air is not needed.

Geset 114te

The "TE" stands for Tamper-Evident and that means that providing indication that a product was not opened is the system objective. This is a modified version to seal products with right angles (squared or rectangular), by placing the labels on the corners of the boxes. Very popular with the pharmaceutical industry but on other fields as well, every time tamper evident labels need to be applied, for example, on boxes of medicine or that contain food. Two Alpha applicators are used, working in Wipe-On mode, and as a result, compressed-air is not needed.

Tamper Evident

System that solves the requirements of the European Directive 2011/62/EU which demands that pharmaceutical products are sealed in a way to ensure that the final customer is the first one opening the box. Two security labels, usually transparent, are applied on both sides of the box. The difference for the Geset 114TE model is that this system does not rely on external Alpha labelers. The system can reach a speed of 78m/min and application rates of 300 labels per minute, for labels with sizes between 20x20mm and 40x40mm, which are usually transparent.

Geset 117

Enhanced version of the Geset 112 model, to apply labels simultaneous on top and bottom of boxes, thanks to a second Alpha labeler. The system can achieve rates of 100 products per hour. The Wipe-On method is used, and as a result, compressed-air is not needed.

Geset 121

Ultra-popular system given its simplicity and efficiency in the labeling of bottles and cylindrical flask. It is a Wrap-Around application, that is, the label is applied along a cylindrical product by going around its entire diameter or only partially if a shorter label is used. The products can have diameters ranging from between 25 to 175mm and can be labeled at heights from 30 to 300mm. With application speeds up to 20m/min, application rates of 80 labels per minute can be achieve, which means almost 5 000 bottles per hour. Compressed-air is not needed.

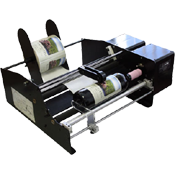

Geset 125

System to label instable cylindrical light products that travel horizontally, that is, lying on the special rolls of the conveyor. This is a Wrap-Around application, that is, the label is applied along the cylindrical, without requiring compressed-air.

Geset 141

This semi-automatic system is very similar to the popular Bottle-Matic, with the difference that a high-quality Alpha labeler is used and with the possibility of installing an optional X1JET HP or X1JET LX inkjet system to print small variable information on the labels, such as, the production and expiration dates and the batch number. The products can be bottles, cans or other cylindrical-shaped articles, with diameters ranging from 15 to 155mm.

Specifications

-

Type

Labeling System with Conveyor

-

Brand

Weber

-

Models

Geset 112

Geset 114

Geset 114te

Tamper Evident

Geset 117

Geset 121

Geset 125

Geset 141

Customized -

Maximum Label Feed Speed

Depends on the model

-

Application Rate

Depends on the model

-

Minimum Label Width

Depends on the model

-

Maximum Label Width

Depends on the model

-

Minimum Label Length

Depends on the model

-

Maximum Label Length

Depends on the model

-

Application Methods

Depends on the model

-

Label Placement

Depends on the model

-

Application Accuracy

±1mm

-

Motor Type

Depends on the model

-

Core Diameter

Depends on the model

-

Unwinder Capacity

Depends on the model

-

Rewinder Capacity

1:1

-

PC Software

None (not needed)

-

User Interface

Depends on the model

-

Protection

IP40 (depends on the model)

-

Ports

Depends on the model

-

Electrical

115 ~ 230V AC, 50/60Hz

-

Weight

30 ~ 535kg (depends on the model)

-

Dimensions (Width x Depth x Height)

Depends on the model

-

Noise Emission

Depends on the model

Alternative Products

-

Alpha Compact 150 ▶︎

Labeler150mm, 40m/min, Wipe-On

RH or LH Versions -

Alpha Compact 120 TB ▶︎

Labeler120mm, 50m/min, Tamp-Blow

RH or LH Versions -

Alpha HSM 135 ▶︎

Labeler135mm, 100m/min, Wipe-On

RH or LH Versions -

Bottle-Matic ▶︎

Semi-Automatic Labeler406mm, 115mm/s, Wrap-Around

For Bottles and Cylinders

Check Also:

Disclaimer

The final version of the delivered system may not

match entirely with the presented images and specifications.