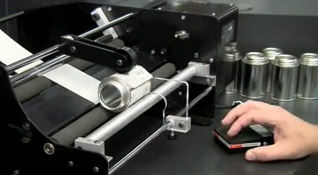

Bottle-Matic

Labeling system with manual product feeding, to apply labels by wrapping them around bottles, cans, tubes and other cylindric objects.

No Complications

These small portable units are perfect to label small batches and they do not require conveyor belts or compressed-air installations.

Excellent Precision

Apply your labels in the right spot with millimeter precision. No more misplaced, crooked or wrinkled labels.

Easy to Setup

This system is very easy to set-up by moving and aligning both the product and label roll guides. The mechanical micro-switch sensor detects the space between labels, even if they are transparent.

With Many Uses

You can apply labels to any cylindrical product, such as, wine and beer bottles, spray or drink cans and tins. Starting from small lipstick tubes and going all the way up to full 5-liter bottles.

Press or Step on It

You can use the trigger switch on the table top and press it as a button or put it on the ground and use it as a pedal.

High Quality Sturdy System

The side frames are laser cut made from quality steel and the rolls are made of 6061-T6 aluminum.

Say Goodbye to Compressed Air

The labeler uses the popular Wipe-On method that besides allowing the application of labels around cylindrical products, it also does all that without needing compressed-air. This means greater cost reductions and less maintenance.

Pick Your Model

There are 4 models, two 10 inches versions and two 16 inches versions, to label bottles up to 250 and 406mm of height respectively. The Bottle-Matic I models are the classic systems to apply a single label per product, while the Bottle-Matic II models execute two applications to apply the front and back labels on the same product.

| Function | I 10" | II 10" | I 16" | II 16" |

|---|---|---|---|---|

| Labels per Product | 1 | 2 | 1 | 2 |

| Minimum Product Diameter [mm] | 12,7 | 12,7 | 12,7 | 12,7 |

| Maximum Product Diameter [mm] | 254 | 254 | 254 | 254 |

| Maximum Product Width [mm] | 250 | 250 | 406 | 406 |

| Minimum Label Width [mm] | 12,7 | 12,7 | 12,7 | 12,7 |

| Maximum Label Width [mm] | 203 | 203 | 381 | 381 |

| Minimum Label Length [mm] | 12,7 | 12,7 | 12,7 | 12,7 |

| Maximum Label Length [mm] | 635 | 635 | 635 | 635 |

| Maximum External Roll Diameter [mm] | 228,6 | 228,6 | 228,6 | 228,6 |

| Feed Speed [mm/s] | 114 | 114 | 114 | 114 |

Specifications

-

Type

Semi-Automatic Labeling System

-

Brand

Weber

-

Models

Bottle-Matic I 10"

Bottle-Matic II 10"

Bottle-Matic I 16"

Bottle-Matic II 16" -

Feed Speed

114mm/s

-

Application Rate

Approx. 1000 products per hour (with label length of 178mm)

(depends on operator's dexterity) -

Minimum Product Diameter

12,7mm

-

Maximum Product Diameter

254mm

-

Minimum Label Width

12,7mm

-

Maximum Label Width

203mm (Bottle-Matic 10")

381mm (Bottle-Matic 16") -

Minimum Label Length

12,7mm

-

Maximum Label Length

635mm

- Application Methods

-

Label Placement

-

Wrap-Around

Wrap-Around

-

-

Application Accuracy

±1,6mm

-

Motor Type

2 AC motors

-

Core Diameter

25 ~ 76mm

-

Unwinder Capacity

228,6mm External Diameter (approx. 450m)

-

Rewinder Capacity

Optional 1:1

-

PC Software

None (not needed)

-

User Interface

Push button for application (can be used as a pedal)

-

Electrical

115/220V

-

Weight

7,7kg (Bottle-Matic 10")

12,7kg (Bottle-Matic 16") -

Dimensions (Width x Depth x Height)

381mm x 432mm x 203mm (Bottle-Matic 10")

534mm x 432mm x 203mm (Bottle-Matic 16")

Alternative Products

-

Geset 141-P ▶︎

Print-Apply SystemSemi-Automatic Wrap-Around

LH Version -

Geset Lines ▶︎

Labeling LinesDifferent Application Methods

Multiple Systems

Check Also:

Disclaimer

The final version of the delivered system may not

match entirely with the presented images and specifications.