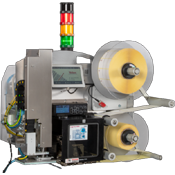

Legi-Air 6000

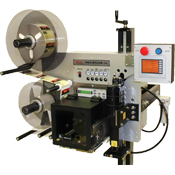

A modern print-and-apply system which is powered by a servo motor to move the application arm at lightning speeds. For that reason, not only the system is 50% faster than the models that use air-pressure cylinders to perform the movement, but also, the reductions on compressed-air costs go to the roof. The applicator still needs compressed-air to hold and blow the label against the product, but the consumptions are very low. The system supports several types of applicators for different application methods.

Apply Labels at High Speeds

Do not limit your productivity! With the Legi-Air 6000 you can print the batch number and expiration date on your pre-printed label or print the whole label when you really need it, moments before its application onto the product. The system can reach really high application rates, even when the arm needs to travel long stroke distances. The label on tamp sensor and the low label sensor are included.

Unbelievable Application Rates

With an ultra-light applicator made of carbon fiber and a servo motor, it is possible to reach rates of 2250 cycles per hour even if the arm needs to travel a long stroke distance of 500mm and large DIN A6 sized labels (105x148mm) are used, that is, the recommended dimension for GS1 labels for boxes and pallets. We are talking about around 40 labels per minute for that scenario. Now just try to imagine the application rates that can be achieved with shorter strokes and smaller labels.

Excellent Precision

Apply your labels in the right spot with millimeter precision. No more misplaced, crooked or wrinkled labels.

"Just-in-Time" Printing

The problem of keeping stocks of labels with variable information that eventually gets obsolete is a thing of the past. Printing the labels when you really need them saves time, money and prevents headaches.

Compatible with most Print Engines

You can equip your Legi-Air 6000 with a thermal-transfer printer module from any of the famous brands like Zebra®, Sato®, Datamax®, among many others, to print labels with good quality.

With Industrial Console

Quickly configure the system using the controller with a digital display. Navigate through the menus with ease, change parameters and read the system's status messages.

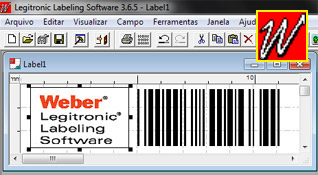

Use All the Features of the System

You can use any compatible software with the print engine that you have picked, but it is with Legitronic® that you can take full advantage of your printer. You can create simple or complex labels, with GS1 barcodes and RFID data and start the print jobs. Learn more about the things that you can do with the software in Legitronic.

Different Applications

You can install several applicators on the system to perform simple and single applications on the top or on the side of the products with a linear stroke arm, or on the front or rear using rotative tamps. All that without needing to stop the conveyor line. The applications can be made with or without contact with the products. With a single stand, you can adjust the system to apply on any position and the systems are available in left- or right-hand versions (LH/RH).

Easy to Use

This system is very easy to set-up. You just need to calibrate the printer to the label size being used, just like it is done for any other desktop label printer. Then, simply submit a print job and the applicator automatically synchronizes with the printer, catching the label and applying it onto the product that was detected by a sensor.

Few Stops

With an unwinder that allows big label rolls and a rewinder for the label liner that works in 1:1, that is, with capacity to rewind the complete roll, you will have to make few stops to do label roll replacements. And we can supply label rolls with the right amount that you need so that during the stops you can replace both print ribbon and the label roll at the same time.

Label Counter

On the digital HMI, you will have a label counter so that you know how many application cycles were performed. The counter has a capacity for 100 000 applications and then starts over automatically.

High Quality Sturdy System

These labelers are very robust and reliable, with a lifespan that goes over 10 years. Built exclusively with quality materials, you will not find a single speck of rust and, besides the occasional cleaning of possible label adhesive build-up, they do not require neither lubrication or maintenance.

Safe and Certified Systems

These systems have CE certification and follow all European safety norms. Most of the standard system are complete complying systems (CC) with the safety norms and do not require additional protections or safeguards, given the fact that they do not exert forces over 50N. When the application rate is critical, there are faster versions in which the system is unlocked to go beyond the 50N of force threshold, being these versions identified as NC (not completed), since they require additional safeguards. If you choose a NC version, the system will include door-open sensors that will immediately halt the labeling operation when the safeguards are opened, so that the system cannot cause injuries. Furthermore, they also bring emergency kill switches to immediately stop the system manually.

Easy Integration: Control the System

The system can send and receive several signals. As input signals, the system can execute the typical triggers to start the label printing process, extend the tamp and apply the label. The applicator can be configured to divide the 3 steps of a cycle (print, extension and application blow) or unite the extension and blow in one task and the label printing can be set to start automatically (when there is print data) as soon as the cycle begins. There are more input signals, like the reprint signal, very useful when a scanner is used to check the printed label.

Easy Integration: Get Status Information

The system makes available several output signals, such as, the information if the system is ready, if there are errors, if the tamp is in the home position, if there is data on the printer, if the printer is feeding (i.e., printing), if the printer is in error, if the label is on the tamp pad, among other signals. You can also configure a synchronization signal that becomes active after the product's detection and deactivates at the end of the cycle, when the tamp returns to the home position, or to simply send a pulse after each application.

Approved by System Integrators

With the Weber® policy for Global Export, the system integrator companies can export our print-and-apply systems as part of a bigger system and the final user gets all the technical support in the destination country, performed by the local distributor of that said country, all completely transparent and without additional costs. All that a system integrator must do is mention that the system is for resale and when the destination country is known, inform us about it so that we can proceed with the transfer of responsibility of the system to the local distributor.

Many Application Methods

You can equip your Legi-Air 6000 with one of several available applicators so that the system can be perfectly adapted to your products and type of application. With linear applicators with short strokes for high speeds or long strokes up to 1200mm for products with big height differences and rotative applicators, there is a model that is perfect for your specific application.

Specifications

-

Type

Print and Apply Labeling System

-

Brand

Weber

-

Models

Legi-Air 6000 LH (Left-Hand Version)

Legi-Air 6000 RH (Right-Hand Version)*Each model has several options of type and length of the arm

-

Print Engine

Zebra, Datamax, Sato, Novexx, Avery or CAB (pick yours)

-

Maximum Print Speed

406mm/s (depends on the equipped print engine)

-

Print Resolution

600dpi (depends on the equipped print engine)

-

Application Rate

>40 labels per minute (depends on the application)

(even when traveling strokes of 500mm and using DIN A6 labels) -

Minimum Label Width

50mm

-

Maximum Label Width

120mm (depends on the equipped print engine)

-

Minimum Label Length

40mm

-

Maximum Label Length

200mm

-

Application Methods

Tamp-Blow

Tamp-On

Blow-On

Tamp-Swing

Tamp-Blow with Rejection Pad RFID

(depends on the chosen applicator) -

Application Stroke

Adjustable up to 1200mm (depends on the model)

-

Label Placement

-

Top

Top

-

Side

Side

-

Front

Front

-

Rear

Rear

(depends on the model)

-

-

Application Accuracy

±1mm

-

Motor Type

Servo (Arm) + Stepper (Rewinder/Unwinder) + Printer's Motor

-

Core Diameter

76mm

-

Unwinder Capacity

350mm External Diameter (approx. 600m)

-

Rewinder Capacity

1:1

-

PC Software

Legitronic (recommended, not included)

-

User Interface

HMI with Digital Display

-

Ports

1x Product Sensor

1x Alarm Lamp

1x HMI

1x I/O

1x Printer

1x Power Connection

+ Printer's Ports -

Electrical

90 ~ 260V AC, 50Hz / 5A

-

Compressed Air

6bar

-

Weight

Approx. 100kg (depends on the model)

-

Dimensions (Width x Depth x Height)

(depends on the model)

-

Typical Accessories

Reinforced Stand

Product Sensor

Proximity Sensor on Tamp-Pad (variable stroke)

Alarm Lamp

Rejection Tamp

more accessories

Alternative Products

-

Legi-Air 4050E Gen3 ▶︎

Print-Apply SystemDifferent Applicators

RH or LH Versions -

Legi-Air 4050B ▶︎

Print-Apply SystemDifferent Electric Applicators

RH or LH Versions -

Legi-Air 5300 ▶︎

Print-Apply SystemDifferent Applicators

RH or LH Versions -

Legi-Air AP182 ▶︎

Print-Apply SystemPallet Applicator (3 sides)

RH or LH Versions

Check Also:

Disclaimer

The final version of the delivered system may not

match entirely with the presented images and specifications.